What Quality Control Testing Really Means in Manufacturing

Quality control testing isn’t just about checking finished products for defects. It’s a system built into every step of production to catch problems before they happen. In generic manufacturing-whether you’re making circuit boards, medical devices, or plastic housings-this process keeps customers safe, reduces waste, and saves money. The goal isn’t perfection; it’s consistency. One faulty batch can cost tens of thousands in recalls, lawsuits, or lost trust. That’s why smart manufacturers don’t wait until the end to test. They test at every stage.

Step 1: Define Clear Quality Standards

Before you start production, you need to know exactly what “good” looks like. This isn’t vague. It’s measurable. For example, a plastic part might need a surface roughness of Ra 1.6 μm, not 3.2. A circuit board must pass electrical resistance tests within ±5%. These numbers come from engineering specs, customer requirements, and industry standards like ISO 9001:2015 or IPC-A-610 for electronics.

Too many factories skip this step or write vague guidelines like “inspect for visible flaws.” That leads to inconsistent results. A good standard includes tolerances, measurement methods, and acceptable defect levels. If you’re making medical devices, you follow FDA 21 CFR Part 820. If you’re in pharma, it’s 21 CFR Part 211. No exceptions.

Step 2: Implement the Right Inspection Methods

Not all defects can be seen with the naked eye. That’s why tools matter. Dimensional checks use calipers, micrometers, or laser scanners. Surface finish is measured with profilometers. Color consistency? That’s tracked using the CIELAB scale, where ΔE under 2.0 means the color match is invisible to the human eye.

Electronics need automated optical inspection (AOI) machines to spot solder bridges or missing components. Pharmaceuticals use spectroscopy to verify chemical composition against ASTM E415 standards. For high-risk items like surgical implants, 100% inspection is mandatory under ISO 13485. For lower-risk products, statistical sampling using ANSI/ASQ Z1.4-2013 works fine-usually sampling 50-125 units per batch based on defect severity.

The key is matching the tool to the risk. Don’t use a $50,000 X-ray machine to check a plastic screw. But don’t rely on a flashlight to inspect a pacemaker.

Step 3: Train Your Team Like Professionals

Technology can’t replace human judgment. A machine might flag a scratch, but only a trained operator knows if it’s a surface flaw or a structural crack that could fail under stress. Training isn’t a one-hour video. It’s hands-on, repeated, and certified.

Operators handling critical components need 16 to 40 hours of training, depending on complexity. They learn how to use tools, interpret data, and document findings. Many companies require ASQ CQE (Certified Quality Engineer) certification for quality leads. But frontline staff? They need to pass practical tests-like identifying 10 known defects in a sample batch with 95% accuracy.

One manufacturer in Melbourne saw a 40% drop in misclassifications after introducing monthly re-certification drills. People forget. Skills degrade. Training isn’t an expense-it’s insurance.

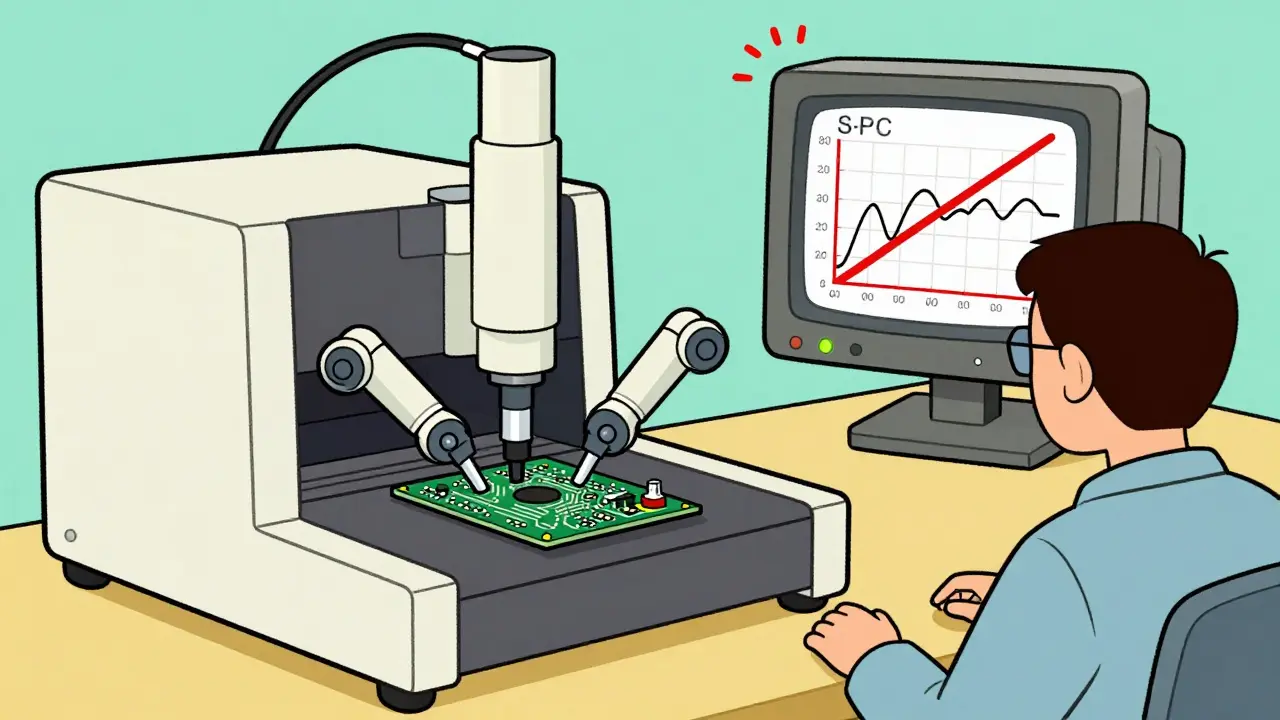

Step 4: Monitor Processes in Real Time

Waiting until the end of the line to find a problem is like driving with your eyes closed. Modern manufacturing uses sensors, IoT devices, and automated data loggers to track variables as they happen. Temperature in a curing oven. Pressure in a hydraulic press. Voltage in a circuit. All recorded every few seconds.

Statistical process control (SPC) charts-like X-bar and R charts-plot this data in real time. If a value crosses the 3σ control limit, the system alerts the supervisor. No waiting for a daily report. No guessing. Just immediate action.

Siemens’ Amberg plant uses this method. They detect defects 27% faster than traditional factories. That’s because they don’t wait for the product to be finished. They watch the process itself.

Step 5: Analyze Results with Data, Not Guesswork

Don’t just collect data-use it. Spreadsheets won’t cut it anymore. Manufacturers use software like Minitab or JMP to find patterns. Is one machine consistently producing parts with higher vibration? Is a specific supplier’s raw material causing more rejects? Are defects clustered around shift changes?

Cp and Cpk indices tell you if your process is capable. A Cpk above 1.33 means your process is centered and tight enough to meet specs consistently. Below that? You’re rolling the dice.

One electronics maker found that 68% of their defects came from just two out of 12 assembly stations. They fixed those two, and overall scrap dropped by 41% in six weeks. That’s the power of data-driven analysis.

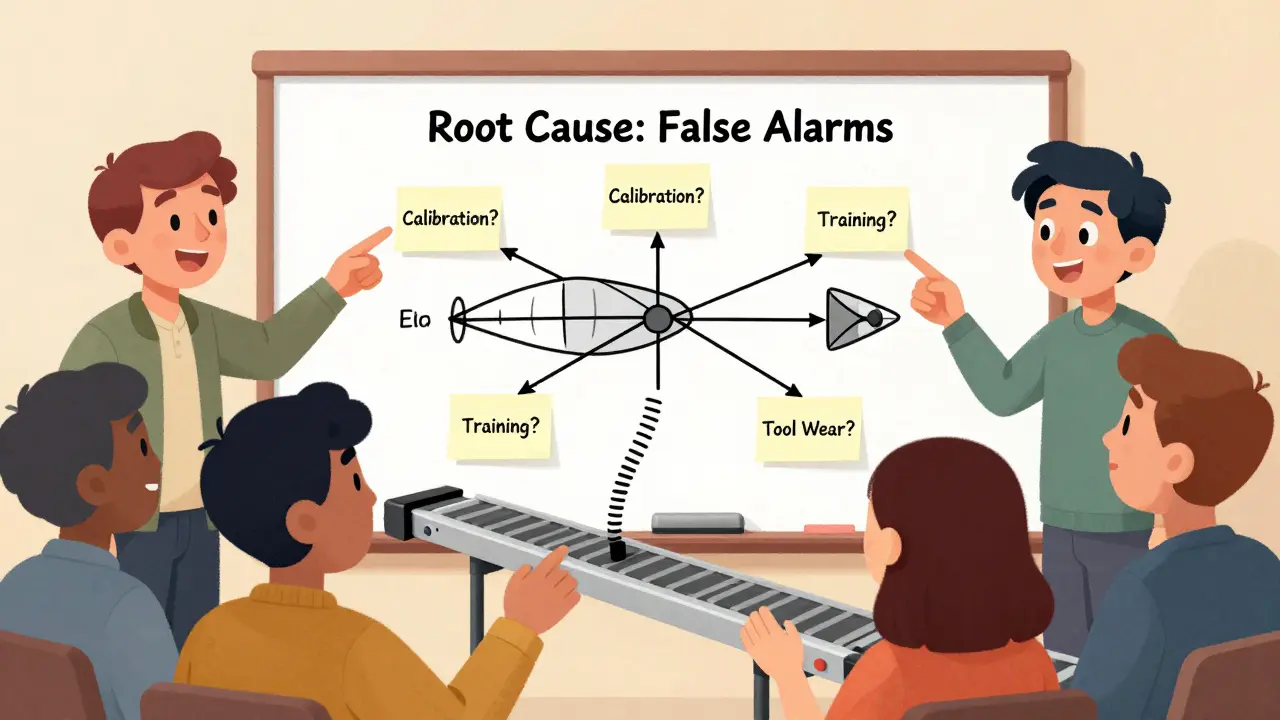

Step 6: Take Corrective Action-Fast

When a defect is found, you don’t just fix the part. You fix the system. That’s called CAPA: Corrective and Preventive Action. It’s not optional. It’s required by ISO 9001 and FDA regulations.

A good CAPA process has five parts: document the issue, investigate the root cause (using tools like 5 Whys or Fishbone diagrams), implement a fix, verify it works, and update procedures. And you have to do it within 72 hours-especially in pharma or medical devices.

One company kept getting false alarms from their AOI machine. Instead of adjusting sensitivity, they dug deeper. Turned out, the conveyor belt was vibrating slightly, causing boards to tilt during inspection. They added dampeners. False alarms dropped 90%. That’s real problem-solving.

Why This Matters More Than Ever

Manufacturing quality control isn’t just compliance. It’s competitive advantage. Companies that invest in full QC systems reduce scrap and rework by over 30%, according to the American Society for Quality. Automotive makers spend up to 5.8% of revenue on quality. Consumer goods? Around 3.2%. But the return? Lower warranty claims, fewer recalls, and stronger customer loyalty.

And the tech is evolving. AI-powered visual inspection is now used by 37% of Fortune 500 manufacturers-up from 12% just three years ago. Digital twins simulate production before it happens. Augmented reality guides inspectors with step-by-step overlays. Blockchain keeps tamper-proof quality records.

But here’s the truth: none of that matters if your team doesn’t understand the basics. Walter Deming said it 40 years ago: quality comes from the system, not the worker. Build a system that prevents errors, train people to trust it, and use data to keep improving. That’s how you build quality that lasts.

Common Pitfalls to Avoid

- Over-relying on sampling: If you sample 100 out of 10,000 parts and miss a batch defect, you’ve just shipped bad product. Know when to go 100%.

- Ignoring calibration: A misaligned micrometer can make every part look wrong. Calibrate tools monthly-or weekly in high-volume lines.

- Not validating test methods: The FDA issued 43% of its 2021 Form 483 warnings for unvalidated QC tests. If you can’t prove your test works, it’s useless.

- Blaming operators: 68% of facilities report inconsistent adherence to QC steps. That’s usually a training or process flaw, not laziness.

- Delaying CAPA: If you don’t fix the root cause within 72 hours, the problem comes back. Guaranteed.

What’s Next for Quality Control

The future of QC is faster, smarter, and more connected. By 2026, 65% of manufacturers will use real-time IoT sensor data to predict defects before they happen. Digital twins will let you simulate 10,000 production runs in a day. AI will spot patterns humans miss-like a slight color shift that predicts a material batch failure.

But the core won’t change. It’s still about defining standards, training people, measuring accurately, and fixing problems fast. The tools get better. The principles don’t.

If you’re starting out, begin with Step 1: write down what good looks like. Then build from there. Don’t buy fancy machines. Fix your process first. The technology will follow.

What are the 6 key steps in quality control testing for manufacturing?

The six key steps are: 1) Define clear quality standards with measurable tolerances, 2) Implement appropriate inspection methods and tools for each product type, 3) Train and certify all personnel involved in QC tasks, 4) Monitor production processes in real time using sensors and SPC charts, 5) Analyze collected data with statistical software to identify trends and root causes, and 6) Take documented corrective and preventive actions (CAPA) within 72 hours of identifying a defect or deviation.

How often should quality control equipment be calibrated?

Calibration frequency depends on usage, environment, and manufacturer recommendations. High-use tools like micrometers or torque wrenches in production lines should be calibrated monthly. Less-used equipment can be calibrated quarterly. Critical devices in regulated industries (like medical or pharma) often follow strict schedules-sometimes weekly. Always document calibration dates and results. If a tool is dropped or damaged, recalibrate immediately, regardless of schedule.

What’s the difference between quality control and quality assurance?

Quality control (QC) is about inspecting and testing products to find defects. It’s reactive-checking output. Quality assurance (QA) is about preventing defects by designing good processes. It’s proactive-building quality in from the start. QC says, “Is this part good?” QA says, “How do we make sure every part is good?” Both are needed. QA sets the rules; QC checks if they’re followed.

Which industries require the strictest quality control testing?

Pharmaceuticals, medical devices, aerospace, and automotive manufacturing have the strictest requirements. Pharma follows FDA 21 CFR Part 211 and requires full traceability, test method validation, and sterile environments. Medical devices must meet ISO 13485 and often require 100% inspection of critical components. Aerospace demands zero tolerance for variation-every bolt, wire, and weld is documented. Automotive follows IATF 16949, which includes advanced product quality planning (APQP) and failure mode analysis.

Can small manufacturers afford quality control testing?

Yes-and they need it more than large ones. Small manufacturers can start with low-cost, high-impact steps: define clear standards, use basic calipers and gauges, train staff on visual inspection, log every defect, and fix the top 2-3 causes. You don’t need AI or automated machines. A $200 digital micrometer, a notebook, and a daily 15-minute team huddle to review defects can cut scrap by 50%. The cost of one recall or lost customer far outweighs the cost of basic QC.

What happens if a company fails a quality control audit?

Consequences vary by industry. In pharma or medical devices, an FDA audit failure can lead to a Form 483 warning, product seizure, or production halt. In automotive, failing an IATF 16949 audit can mean losing contracts with major OEMs. Even in general manufacturing, customers may terminate contracts or demand price discounts. Beyond financial loss, reputation damage can take years to repair. The fix isn’t just fixing the audit findings-it’s rebuilding trust through transparent, documented improvements.

Fabio Raphael

December 27, 2025 AT 02:57Training isn't a checkbox. It's the backbone.

sakshi nagpal

December 27, 2025 AT 22:54Sophia Daniels

December 28, 2025 AT 03:32AI vision systems detect micro-cracks before the human eye blinks. Digital twins simulate 10k runs overnight. If your QC process doesn't have a neural net in it, you're not manufacturing-you're babysitting broken machines.

And no, 'monthly calibration' is not enough. If your torque wrench is older than your intern, replace it. #QualityIsDeadIfYoureNotTechSavvy

Steven Destiny

December 28, 2025 AT 12:19Don't wait for disaster. Start with Step 1. Write it down. Then build from there. No excuses.

Natasha Sandra

December 28, 2025 AT 23:10My cousin works at a plastic injection place and they use a flashlight to check seams. A FLASHLIGHT. 😭

They also blame the new hires every time something goes wrong. No. It's the process. Fix the process. Not the people. ❤️

Erwin Asilom

December 30, 2025 AT 05:26Sandeep Jain

December 31, 2025 AT 05:28roger dalomba

December 31, 2025 AT 06:56Brittany Fuhs

December 31, 2025 AT 09:40Nikki Brown

January 1, 2026 AT 04:45And don't even get me started on AI replacing humans. We're not robots. We're not data points. 😔

Peter sullen

January 2, 2026 AT 14:14Sumler Luu

January 3, 2026 AT 19:56Just write it down. Even if no one else does. Someone will need it someday.